All Ice Cream Shop Supplies You Need For Your Store

Starting an ice cream store is no doubt a treat, but the task of outfitting it with the proper machines and tools can give you brain freeze.

A crucial step in the process is identifying and finding the right equipment that will serve your business and concept well. These machines will play a huge role in the quality of your service and profitability of your business. They will fuel the production and productivity of your operation.

With that in mind, we’ve put together a definitive list of ice cream store equipment below to help you get started on this part of the journey.

Type of Ice Cream

- You won’t have to make your own ice cream to get into the business. You can get your store off the ground by serving ready-made ice cream. This is an affordable and more manageable route that entrepreneurs can take advantage of. All you have to worry about as far as equipment goes will be proper storage and display, which we discuss below this section. Managing inventory will be much easier as well.

The catch is that it may not be as profitable as making your own ice cream, which offers more room for you to get creative and add variety to your offerings that customers will appreciate. You can, however, transition into in-house production at some point if you initially designed your space to do it.

Ice Cream Production

Batch freezers and soft serve machines are the most common pieces of equipment used in producing ice cream for small to medium-scale ice cream stores. Most machines are designed to produce 30-35% overrun, but there are some units that can go up to 80%.

What is overrun? Overrun or the amount of air introduced in the ice cream during production. The percentage of overrun constitutes the increase in the volume of the product. The higher the overrun, the more product you get to make, which means higher profits. Too much air, however, can be perceived as a sign of low-quality product. This is because the amount of air in the ice cream also influences its texture and consistency. The less air the product contains, the denser and creamier it becomes. Excessive air could make for a bland ice cream. If it’s there barely any overrun, you get a frozen block your scoop wouldn’t have a chance to break through. Ingredients can influence overrun, but the configuration of the machine can also make an impact. |

Batch Freezers

Designed to produce batch after batch of ice cream, frozen yogurt, gelato, sorbet, custard or other frozen dessert, a batch freezer is an absolute must-have for an ice cream shop looking to make the product on site. These machines can produce a huge batch of ice cream in just 8-10 minutes.

Product mix is poured into the product chute of the freezer. It will be chilled and churned in the frozen cylinder by a beater or dasher, which rotates at 100 to 120 revolutions per minute (rpm) to introduce air into the mix and scrape product from the barrel’s cold sides back to the barrel so that it gets colder and thicker.

Some units have two speeds designed for hard ice cream and gelato. The more expensive batch freezers allow you to set the overrun for each batch. For assured quality, many ice cream stores like to stay in the middle.

Batch freezers usually have alarms or prompts to let you know that the product is ready, which you can then retrieve from the extraction chute. Bulky flavorings such as cookies, fruits, and nuts can be added as the product is extracted to prevent damage to the chunks. However, very few units allow such ingredients to be added during mixing to achieve an even distribution, which can be harder to achieve if you do it as the product comes out.

Batch freezer capacities are measured in quarts. You can get a unit as small as 3 quarts and you can go all the way to 44 quarts. Small to medium ice cream stores can get away with a 24-quart.

When choosing the capacity of the unit, account for the overrun. If you get 50% overrun on a 2-gallon mix, you’ll end up with 3 gallons of ice cream, which means you would need a 12-quart machine.

Some configurations of batch freezers come with a separate cylinder for heating. This type of freezer allows you to combine and heat the base and flavor to create a flavor base that will then be moved to the frozen cylinder. This design is useful to gelato shops and ice cream makers who want a greater degree of control of the flavor of each menu item.

Soft Serve Machines

If you are looking to have soft serve or frozen yogurt on the menu, you will need a machine specialized to produce such product. A soft serve machine adds a greater amount of air to the ice cream mix and maintains it at a higher temperature to achieve the lighter consistency and softer texture of these type of frozen desserts. The ice cream is held in this state for long periods and can be directly dispensed into a cup or a cone whenever a customer orders.

Soft serve machines are either floor and countertop. Units can hold up to two flavors, but there are twist serving units that allow you to mix these flavors into a twirl.

Single flavor soft serve units can produce 3.5 gallons of soft serve per hour, which is good for 100 orders. Twist units have a 15-gallon capacity per flavor. For a large production, soft serve machines with up to 50 gallons of capacity are also available.

Soft serve machines are either gravity-fed or pressurized. In the former, operators simply manually load the mix and the unit does the rest. This type of soft serve machine relies on gravity to push the mix into the cylinder, which tends to limit the amount of air introduced into the product to just at 42%.

Pressurized units, on the other hand, produce higher overrun at 60 to 80%. They use pumps with different ranges of pressure depending on the brand that push the mix into the cylinder, offering a better control of the air ratio in the product. For this reason, these units are pricier than the gravity-fed versions.

Ice Cream Hardening and Storage

Storage and handling of ice cream should be done with care. This product is perishable and should always be kept at the ideal temperature to preserve its quality and to keep customers happy.

Hardening Cabinets

A hardening cabinet preserves the best possible state and quality of the ice cream.

Ice cream comes out of a batch freezer at a temperature of 16 °F. By force-circulating air all over the product using fans, a hardening cabinet freezes the ice cream to -30 or -40 °F in four to 10 hours.

By freezing ice cream rapidly, you prevent the formation of large ice crystals that can sully the taste and texture. Freezing at the shortest amount of time possible also allows you to capture and permanently set the original structure and creaminess of the ice cream. Plus, it protects against heat shock and discourages the growth of bacteria for a longer shelf life.

In turn, hardening cabinets bring the labor down. Ice cream stores can prepare and preserve ice cream in bulk to keep up with large volume demands and wholesale orders.

Hardening cabinets are designed to accommodate up to 43 3-gallon tubs. They come in single, double, or quad door configurations.

Walk-in Freezers

A standard walk-in freezer can maintain temperatures as low as -10° F. If you need a large space for long-term ice cream storage, however, you will need low-temperature units that can get as cold as -20° F.

Some walk-ins can be configured with two different temperatures so you can store items that require different levels of coldness in a single space.

Walk-in freezers operate either with self-contained or remote refrigeration system. The former will take up more space than the latter, but will at least be more manageable and easy to maintain. Remote units will have more space available to you since the refrigeration system is installed outside your establishment.

Prefabricated units come in predetermined sizes, which offer greater leeway for expansion and futureproofing. You can have them customized to your space, but it will be trickier to expand them should you need to.

Remember that -20 °F walk-ins will always require professional installation, but pre-assembled units, which are essentially plug and play, will give you the easiest time.

Chest Freezers

Chest freezers can have a place at both the front and the back of the house, depending on your setup. These freezers operate at a wide temperature range, with most of them able to go down to -10 °F.

Units that feature solid doors for enhanced insulation can be utilized as tempering cabinets for hardened ice cream or Italian ice. Models with sliding glass tops are suitable for self-service access and storage for take-away treats like popsicles, ice cream pints, ice cream sandwiches, and other novelties.

Chest freezers can be a great starting point for entrepreneurs looking to break into the ice cream business. With up to 25 cubic ft. of capacity, these units are excellent and affordable alternatives to a walk-in if you don’t have the budget or the space for one.

Interestingly, some ice cream owners have reported success in the use of chest freezers as the main storage and holding area for freshly made ice cream. However, ice cream with no proper hardening (ideally at -20 °F after it goes out the batch freezer) is bound to have a much shorter shelf life, and should therefore be sold one or two days after it was made.

Ice Cream Pans and Containers

Pans and containers provide the proper surface to store ice cream straight out of the batch freezer. These items have different capacities and are either stainless steel or polycarbonate. They also have lids for total protection and insulation during hardening and storage.

Ice Cream Serving and Display

Ice cream should always be shown at its best to attract customers and keep them coming back. Half of this is excellent presentation, and the variety of flavors and colors the popular dessert comes in provides every opportunity for operators to get creative. The other is storage, which can ruin the appearance and the taste of your creations if not done right. Both will rely on your machine to retain the optimal scooping and serving temperature to be handled perfectly.

Dipping Cabinets

Dipping cabinets are designed to store and preserve ice cream, gelato, and other frozen desserts in the ideal serving temperature during point of sale. These units operate at a temperature range of -10 to 20 °F and they come with simple controls to adjust to the coldness of the environment to the specific product.

For reference, hard ice cream should be perfectly scoopable at 0 to -6 °F. With gelato, you can go up to 12 °F. Italian ice is ideally preserved at warmer temperatures, usually at 10 to 18 °F while frozen custard is best served at 10 to 20 °F.

Dipping cabinets offer storage for a minimum of 3 three-gallon containers to as many as 39. The interior is divided into two separate storage areas. The facing storage keeps a selection of flavors visible to customers while a hidden storage underneath is reserved for backup tubs. This area can be used for tempering ice cream that comes out of the blast freezer.

There are dipping cabinets that come with a top rail that houses syrup jars and pumps as well as cold containers for toppings and a dipping well for a more streamlined preparation.

Visual Dipping Cabinets

Visual dipping cabinets feature a straight or curved front canopy that acts as the main viewing area for customers. Plastic interior shelves are used to house the tubs of ice cream. They are removable so you can easily switch out the containers as needed.

These dipping cabinets have sliding glass lids that provide the staff with quick access to the ice cream when serving it up. They are typically heat reflective to help with maintaining the temperature inside.

Some units have a glass cover that raises and slides along the inside of the front canopy. There are also dipping cabinets with sliding lids over the doors for extra insulation.

Remember that with the total visibility this type of cabinet provides, the display should be free of spills and drips.

Storage Dipping Cabinets

Generally located at the back of the house, storage dipping cabinets feature multiple rows of dual-access stainless steel lids. These units can be used on both newly made ice cream or prepackaged treats.

This type of dipping cabinet is completely enclosed, hiding the tubs from sight. You can fold the lids open from one side to access parts of the interior. This way, only one or two tubs are exposed. The lids can be removed completely for loading items to the cabinet.

These units sometimes come with a refrigerated topping rail that houses syrup jars, pumps, cold topping containers, and dipping wells, so you have everything you need to prepare the ice cream. Depending on the configuration, units have room for 5 to 10 syrup jars.

You can also get a drop-in that fits right into a countertop. You can pack two to four tubs of fresh ice cream in these units, but you can also use them to store prepackaged treats.

Gelato Dipping Cabinets

Dipping cabinets for gelato use trays as containers as opposed to tubs. The view is slightly slanted down to better showcase the flavors. Dedicated gelato units maintain a higher temperature usually at 20 °F to provide the perfect climate for the dense and creamy product.

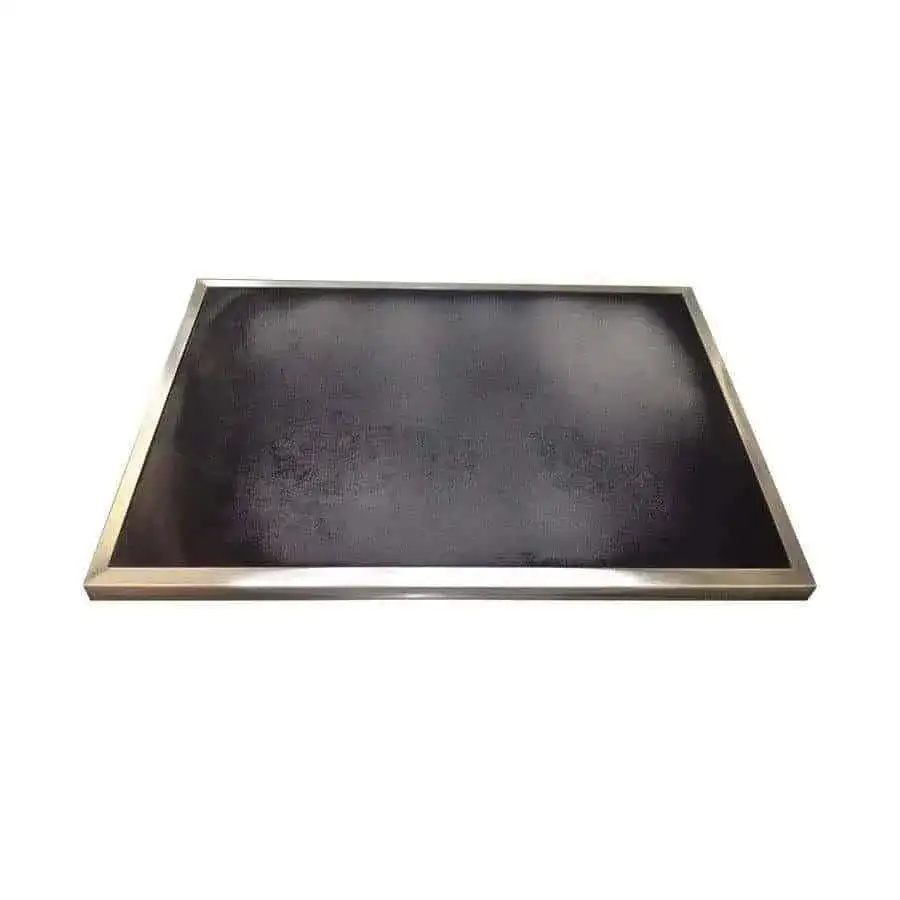

Drop-in Frost Tops and Cold Slabs

Frost tops and cold slabs provide a cold surface where your staff can prepare an ice cream from scratch before the customer’s very eyes.

These units are popular in ice cream stores that offer Thai rolled ice cream or mix-ins, but you can also use them to keep prepackaged or preprepared ice cream or other frozen desserts for display or speedy delivery.

Frost tops and cold slabs both use a self-contained refrigeration system suspended below the cold surface. The main difference between the two is that a cold slab is typically constructed of aluminum or granite with an even surface while frost tops have a recessed surface that can be evened out with pans.

Ice Cream Topping Cabinet

Ice cream topping units have a refrigerated topping rail with room for up to 16 syrup jars and a frozen base for storing and preserving backup toppings.

Reach-In Merchandisers and Display Cases

If you have regular cakes or ice cream cakes on the menu, a reach-in freezer or refrigerator will do a great job of showing them off. You can place them by the entrance or near the counter for better showcase. They are also great for prepackaged desserts, which can help boost take-home sales.

These units come with up to three sections with sliding or swing doors that self-close to avoid spoilage and excess energy consumption. The glass panels and LED or fluorescent lighting keep the items visible and attractive. They come with adjustable racks that could fit up to two cakes depending on the size.

Horizontal refrigerated display cases and dedicated ice cream cake freezers, on the other hand, are shorter in height and can be situated at the counter for immediate staff access. These units generally have wider shelving with up to three racks to display a lineup of beautiful ice cream cakes.

Air-Cooled vs Water Cooled

Before we move on, let’s discuss the type of cooling system that these machines will employ. These freezers either use air-cooled and water-cooled designs to get rid of heat. Each one has its advantages and disadvantages.

Water-cooled freezers are best suited for smaller rooms or locations where temperature is harder to control. These machines cool the condenser using, you guessed it, water, which has better thermal properties compared to air.

Water coils wash up the condenser coils and absorb the heat, flushing the water out of the unit as hot water. This process will require large amounts of water to accomplish. One solution is installing a recirculating water system to reuse the water, but it isn’t easy to do in a commercial building. This would explain the prevalence of air-cooled units.

Air cooling is also the best option for locations with limited water supply or temperature-controlled environments. These units pull in cold air and blow hot air out into the room, which can immediately crank up the temperature in a small kitchen. The fans can cause a lot of noise too.

The upside to air-cooled freezers is that they are easier to set up because you won’t need a water supply line or drain. You might have to get an air conditioner or direct the heat outside using air ducts to maintain a cold environment.

Essential Accessories

Dishers, Dippers, and Spades

Dishers allow you to scoop up a specific portion of ice cream. They are color-coded and assigned a number based on the number of ounces they hold or the number of scoops you can get per gallon. Dishers come in a left-handed or right-handed mechanism, but there are those with a squeeze handle.

Scoops or dippers, on the other hand, are typically used for hard ice cream. They don’t have a lever that helps with scooping and releasing the ice cream. Instead, you simply scrape the ice cream and form it into the traditional classic round shape that ice cream fans know and love. They usually have non-ceramic coating and, like the dishers, have designated number and colors for different ounce capacities. Select brands use defrosting liquid for faster dipping and better protection from crystal formation.

Spades are recommended for retrieving gelato. Its shape will make each serving less uniform in each order, but it helps with removing ice cream from the walls of the containers to avoid waste.

These tools are made of either aluminum or stainless steel. A popular company called Zeroll designs their serving tools to get more scoops out of your tubs by creating the appearance of a large scoop.

Dipper Wells

Dipper wells are used to store and rinse dippers and dishers in between use to keep them sanitary and within arm’s reach at all times. Designed to be mounted on a countertop or a dipping cabinet, these units help prevent bacteria growth and flavor transfer. Dipper wells can hold up to seven scoops.

Topping Warmer

Topping warmers keep liquid toppings like hot fudge and caramel perfectly hot. These are countertop models with adjustable thermostat that can be placed in the prep line or at a self-serve station. They either come with a ladle or a pump that can dispense the product with a push. These units can accommodate one or two flavors with a capacity of 3 quarts for each.

There are also squeeze bottle warmers that store and heat up one to three squeeze bottles of chocolate and other sweet sauces. They are great for self-service or staff use behind the counter. Each bottle compartment typically has its own control knob to adjust the right temperature for each topping.

Topping Containers and Dry Topping Dispensers

Topping containers and dispensers hold a large batch of dry toppings like nuts and candies. They are transparent so the contents are easy to identify and the fun colors of the items are showcased, adding to the aesthetics and merchandising capability of the ice cream store.

Whipped Cream Dispensers

Whipped cream dispensers help you add the finishing touches to your ice cream offerings. Made of aluminum or stainless steel, these cream dispensers use nitrous oxide gas to produce 0.5-1 liter of whipped cream, mousses, and other chilled fluffy sauces that will then be expelled to top off ice cream. These items feature a number of decorator nozzles or tips with unique styles and designs.

Ice Cream Cone Dispensers and Holders

For easy access and display of different kinds of cones available, you can make use of ice cream cone dispensers and holders. Wall-mounted units and cabinet-style holders can accommodate a greater number of cones. The former automatically positions a new ice cream cone every time one is retrieved. There are ice cream cone holders that are designed to hold two to four cones only.

Waffle Makers and Bakers

Waffle cone makers can produce up to hundreds of cones per hour. They usually include forming tools that allow you to mold the waffles into different shapes.

Crepe Maker

A crepe maker features a non-stick cast-iron cooking surface. These units usually come with an adjustable thermostat. The most common BTUs crepe makers come in are 22,000, 24,000, and 48,000.

Drinks

Drink/Spindle Mixers

Spindle mixers or drink mixers blend ice cream, milk, flavored syrups, and tougher ingredients like nuts and candies into a milkshake. They are designed to preserve the richness and thickness that customers want in the frozen drink.

Depending on your demand, you can get drink mixers with one, two, or three spindles. They are packaged with stainless steel malt cups sized to match the typical milkshake glass for quicker and more consistent preparation. Most units come with three speeds, but there are models with variable speed adjustments for precision.

Soda Fountain

A soda fountain makes sodas by mixing carbon dioxide with water using tons of pressure. Every time the tap is pushed, the carbonator of the machine receives water and CO2 and mixes it all together to create carbonated water. A syrup pump then sends in the chosen flavor to combine with the carbonated water. The finished product comes out ready for serving. Some units don’t include syrup pumps to allow operators to add it manually.

Either way, a soda fountain is a truly handy unit for ice cream stores looking to serve carbonated beverages or ice cream sodas. These units feature up to 12 dispensers so you can offer a wide variety of flavors.

Beverage Dispensers

Beverage dispensers provide refrigerated storage and instant access to sodas or juices on demand. Units maintain one to four drinks between 36 to 38 °F in large clear hoppers. Each flavor has a dedicated nozzle for dispensing. Hoppers typically have uniform capacity while some units have one hopper with larger capacity than the others.

Serving Supplies

Serving supplies ensure that not only the orders reach the customers with the quality and presentation intact, but the ice cream experience is made complete and convenient. For starters, napkins and napkin dispensers should always be present at the counter and on every table. Eating ice cream can be messy especially when it starts to melt.

You can play around with different containers when serving the ice cream itself. The usuals include clear or colored plastic cups and bowls that you can get with or without dome and flat lids. Capacities range from 4 ounces to 12 ounces.

A great way to bump up presentation is employing serving dishes and glasses with fun shapes and stainless steel, glass, or hard plastic design like the footed, tulip, scallop rim, and sundae, plus vintage shake glasses for milkshakes. This way, your ice cream and frozen dessert creations will look as good as they taste. Transparent ice cream glasses or clear plastic containers will do a good job of showing off a beautifully crafted frozen treat from every angle.

Use plates for serving crepes or orders with single or multiple scoops topped on waffles, brownies, cakes, and other unique ice cream creations. Paper cold cups can be used for both drinks and frozen yogurt while pleated papers are suited for serving italian ice.

Drinking cups and glasses for sodas and juices should be available as well as dispensers that allow you to store them all in one convenient, easy-to-reach location. Stock up on straws and get a straw organizer to keep them all in one place.

You’ll need spoons for ice cream served in dishes or cups and flatware holders to store them along with other cutlery you may use. Don’t forget take-out containers and pints for customers looking to treat themselves to your ice cream at home.

Sanitation and Safety Supplies

As with any foodservice establishment, cleanliness and safety are of utmost importance. Don’t skimp on anything when it comes to this department.

For your staff that handles and serves the ice cream, hats and hairnets, as well as disposable gloves, will be necessities. Hand soap and dispensers should be nearby so they can sanitize their hands before handling the food.

Keep the back and front of the house sanitary with pest control products and sanitizing chemicals. Clean up melted ice cream, food debris, and dirt from tables and chairs using surface wipes.

Trash cans and recycling bins should be present for your waste management.

Wrapping Up

Ice cream may just be the most recognizable frozen dessert in the whole world and there will always be a business in something like that. How profitable your ice cream store can get will depend on many things, but a lot of it will have to do with the equipment.

Business owners are always encouraged to buy brand new units because you get longer service life out of your equipment, save on maintenance costs, and it just makes life much easier should replacement and support be needed.

If you’re ready to bring your ice cream store to life or if you are still unsure of what configurations and models to get, CKitchen can help you choose the proper equipment and design your kitchen to be at its most efficient and functional.