Everything You Need To Know Before Buying A Commercial Fryer

Fryers are excellent for cooking and crisping foods rapidly to create a crunchy crust and a moist, flavorful inside. Commercial kitchens that produce a lot of fried food products can benefit largely from investing in a high-quality commercial fryer. However, choosing among the many different types of Commercial Deep Fryers and considering all the factors needed to look at can be overwhelming.

In this buying guide, we help you identify the fryer you need. We'll discuss the different types of fryers and the features you want to look for. And of course, some special considerations to pay attention to while making the buying decision.

Types of Commercial Fryers

1. Tube Fryer

Tube fryers have a series of tube-shaped gas-powered heating elements that are permanently attached near the bottom of the frypot. The tubes are completely immersed in the frying oil, which allows for rapid heating and uniform distribution of heat.

Tube fryers are known for their large sediment zones, which are areas inside the frypot where the oil doesn’t get as hot as other zones. This makes it excellent for heavily breaded food items, such as breaded pork chops and fish sticks, because the large amount of sediments can settle in the sediment zone without scorching and affecting the flavor of the oil.

Tube fryers are extremely versatile. They can handle the widest variety of items, including both breaded items and battered goods such as onion rings, mozzarella sticks, and French fries.

Some models have baffles inside the burner tubes, which are zigzag-shaped devices that have holes to allow for sufficient airflow. Baffles are used to ensure optimal heat transfer so that the fryer can make the most out of the available heat. However, baffles in low-end models may easily get damaged over time, causing more heat to escape through the flue and making the fryer use more gas than it is supposed to.

The downside to using tube fryers is that they are difficult to clean. The tubes that usually separate the sediment zone from the rest of the frypot restrict access to some parts of the fryer. If the fryer remains uncleaned for long periods of time, the oil may easily go rancid and destroy the flavor and odor of your fried products.

2. Open Pot Fryer

Open pot fryers are distinguished by their open top. The heating elements aren’t submerged in the oil, making the bottom open and easier to clean than tube fryers. Many open pot fryers have a V-shaped towards the bottom of the frypot. The burners are usually attached outside the frypot just above the area where the bottom tapers into a V.

Because of the narrow bottom, open pot fryers have small sediment zones that can only handle low-sediment food items, such as onion rings and hash browns. They also have longer heat up and recovery times, making them more suitable for small to medium operations where you don’t need to produce a large volume of fried goods all throughout the day.

The unobstructed top of open pot fryers allow you to use fryer baskets that can be lifted out of the frypot when cooking is done. Most open pot fryers are powered by gas, but some models run on electricity. These usually have the heating elements in the oil, creating a more uniform heat distribution and even cooking.

3. Flat Bottom Fryer

Flat bottom fryers are a variation of the open top fryer. These units have a flat bottom, with heating elements attached below, turning the bottom of the frypot into a wide, rectangular heat transfer area to heat up the oil quickly and efficiently.

Cooking in a flat bottom fryer means the heavily battered items sink to the flat bottom first, only rising to the top after they are done cooking and ready to be skimmed off using a mesh fryer skimmer.

Because they have no sediment zones, there’s a risk of burning the sediments that fall of your food items, thus affecting the flavor of your products. This makes flat bottom fryers unsuitable for breaded items. They are best used for dough and batter-based fried foods instead, such as donuts, churros, and tortilla chips.

Even if you don’t use the flat bottom fryer for breaded items, you will still need to install an oil filtration system to regularly remove any sediments from your cooking oil. Not only does this extend the quality of the oil, it also prolongs the lifespan of your fryer.

4. Ribbon Fryers

Ribbon fryers are heated by a thin metal ribbon that snakes around the bottom of the wide, shallow frypot, hence their name. The ribbon-shaped heating element has a bigger surface area, which allows it to transfer heat and heat up the oil faster. Ribbon fryers also recover from cooldown times more quickly so you don’t have to wait for long periods of time between cooking to heat them up again. Most ribbon fryers are powered by electricity. Like tube fryers, ribbon fryers can pose a challenge during cleanup time because the ribbon-shaped heater creates a barrier to some parts of the frypot.

5. Induction Fryers

Induction fryers use an electric and magnetic currents to directly heat up the frypot. These units typically use a coiled copper wire to create an electromagnetic field, which is used to heat up the stainless steel frypot. This is a more efficient method than using heating elements submerged in oil because the electromagnetic field only heats up the cooking vessel. It also heats up and recovers faster, allowing you to fry a succession of batches without waiting in between. While there aren’t many induction fryer models available yet, those currently on the market have precise temperature controls that allow you to keep a close eye on the temperature of your cooking oil.

6. Specialty Fryers

Some fryers are designed for cooking specific types of food. If your commercial kitchen produces large numbers of these food items, you may want to invest in fryers that are made particularly for them.

a. Funnel Cake Fryers

Funnel cake fryers are characterized by wide, shallow frypots and flat bottoms that allow funnel cakes to float to the top of the oil when done. These are usually classified according to the number of funnel cakes they can make at any given time. Funnel cake fryers are typically seen at carnival stands, funnel cake concessionaires, and large outdoor events.

b. Corn Dog Fryers

Corn dog fryers have narrow, rectangular frypots where corn dogs are dipped vertically into the oil to cook. These fryers have clips that hold the corn dog sticks in place. Most models are configured to accommodate a dozen corn dogs at a time. Some units have bigger frypots to accommodate foot-long corn dogs.

c. Donut Fryers

Donut fryers are similar to funnel cake fryers. They have large, wide, and shallow frypots with a flat bottom that allow the cooked donuts to rise to the top. They usually have grates to prevent the donuts from sinking to the heating elements and getting burned. Donut fryers range from small, low-volume units to high-end models that can contain up to 210 lbs. of oil and produce 420 lbs. of donuts in a single use. Premium units may also come with some accessories to make food production more convenient, such as a drainboard to drain off excess oil before serving.

d. Outdoor Fryer

Outdoor fryers are built on durable casters that allow them to be moved around. These are typically made with heavy-duty construction that allow them to withstand wind, rain, sun, and the elements. Outdoor fryers are normally used at street fairs and outdoor catering events.

e. Ventless Fryers

For commercial kitchens that don’t have space for a commercial hood, ventless fryers are the solution. These units have catalytic converters, which remove grease, fumes, and vapor from the air. They also remove heat to help make sure the kitchen remains a comfortable working space for your staff. Most localities do not require kitchens that use ventless cooking equipment to install a hood system. Operations with small kitchens, such as sandwich shops and c-stores, benefit greatly from using ventless fryers.

7. Pressure Fryers

Pressure fryers work similarly to pressure cookers. They keep the frypot under huge amounts of pressure to heat up the oil faster than standard fryers. This creates very short cooking times and tender, juicy fried food products. National fast-food chains are known for using pressure fryers to create golden brown, crispy fried chicken with moist, flavor insides. However, pressure fryers can only cook food that is 1/4 the weight of oil used per batch. For example, if you’re using 100 lbs. of oil, you can only produce 25 lbs. of fried food products for each batch.

Features to Look for in a Commercial Fryer

1. Tanks

Fryer tanks are the compartments that contain the oil for frying. You can choose between single-tank models or twin-tank or multiple-tank fryers. Single-tank fryers are great if you’re frying only one type of food product at a time. These can accommodate large fry baskets and are useful for high-volume frying during the busiest times of the day. Twin tanks, on the other hand, allow you to cook different types of food products at the same time without the risk of flavor transfer. If you’re cooking different meat products simultaneously, twin tanks reduces the risk of cross contamination. These can also be more energy-efficient than single tanks, especially during the slow days where you don’t have to use the entire fryer to prepare your food products. You can simply heat up one tank if it’s enough to accommodate all your items and keep the other tank unused.

2. Sediment Zone

When bread crumbs or other bits and pieces of food fall off from your items as they’re cooking, they tend to collect at the bottom of the frypot. If not removed, these sediments turn into carbon residue that looks like small bits of coal in a process called carbonization and ruin the flavor of your food products and negatively affect the quality of your cooking oil, making it brown quicker and faster to smoke.

Sediment zones prevent the carbonization of sediments and prolong the quality of your oil and equipment. Also called cool zones, these are areas in the frypot where the oil doesn’t get as hot as in other areas. The oil is still hot but is not hot enough to burn the sediments into a carbonized crisp.

Having easy-to-access sediments make the fryer easier to clean and maintain. Some fryers may have lift-out heating elements, where the elements can be lifted out to make cleaning the sediment zone easier.

3. Filtration

A sediment zone is not enough to maintain the quality of the oil. You need to invest in an oil filtration system to make sure all sediments are removed. The longer the cooking oil goes unfiltered, the more likely the quality of your food product will diminish. Oil filters remove the solid particles from the oil to prevent carbonization and the breaking down of the oil.

Filtration systems can either be built into the fryer or bought separately. Fryers with built-in filtration systems are more expensive upfront, but the equipment pays for itself in the long run in terms of better performance and less oil usage. They are also very easy to use, only requiring a push of a button to get started. Built-in filtration systems can typically clean vats of oil in a few minutes. Some high-end filtration systems even provide continuous filtration, ensuring that the oil is completely devoid of sediments that can affect the flavor and quality of the food.

Portable filtration systems are not as user-friendly but are still easy to use. Most systems have a nozzle that you have to place in the frypot. The oil filters will then remove all sediments from the oil and clean it food particles, proteins, and acids that affect its flavor.

4. Fryer Basket and Basket Lifts

Fryer baskets are typically steel-plated mesh baskets that hold your food items while they’re cooking. They usually have plastic handles at one end to make them cool to touch and hooks at another end so they can hang on a basket hanger. Single-tank fryers allow you to use several baskets at a time so you can cook bigger batches in one session.

Some high-end models are equipped with basket lifts, which are programmed to automatically lift the basket once a pre-programmed cooking time has elapsed. This ensures your food items are not overcooked and helps prevent food wastage.

5. Programmable Controls

Newer models of fryers come with programmable controls that let you adjust multiple settings according to your preferences. You can set precise cooking temperatures for specific food products. Regular French fries, for example, can be cooked at slightly lower temperatures than shoestring fries and basket weave fries. Some fryers may even have sensor-based thermostats, which automatically lower the temperature of the oil if the thermostats detect dangerously high levels. You may even program a fryer to notify you when cooking is complete, helping you save time by focusing on other tasks while the food is frying.

6. Automated Top Off System

Fried food absorbs around 10% of the oil used to cook it. This means you’re losing 10 lbs. of oil for every 100 lbs. of food products produced through the fryer. It’s important to keep an eye on the amount of oil inside the frypot to prevent it from drying up and burning the food. However, consistently adding oil to the fryer can be a tedious job for cooks.

An automated top off system does the job for you. Found in some high-end units, this feature automatically pours oil into the frypot when it detects that the oil is below a certain level. The system is connected to a container of oil typically found next to or below the fryer.

Factors to Help You Choose a Commercial Fryer

1. Models

Whether you choose a countertop fryer or a floor model, you will need to make your decision based on how much food you need to prepare regularly and how much space you have in your kitchen.

a. Countertop Models

Countertop models are most suitable for commercial kitchens that don’t have plenty of real estate and don’t need to prepare a lot of fried foods every day. Delis, sandwich shops, and low-capacity restaurants are better off with countertop models.

However, just because they’re compact in size doesn’t mean there are no options for heavy-duty use. Countertop fryers run the gamut from light-duty electric models to medium-heavy-duty and heavy-duty units that can produce the same volumes as small to medium-capacity floor models.

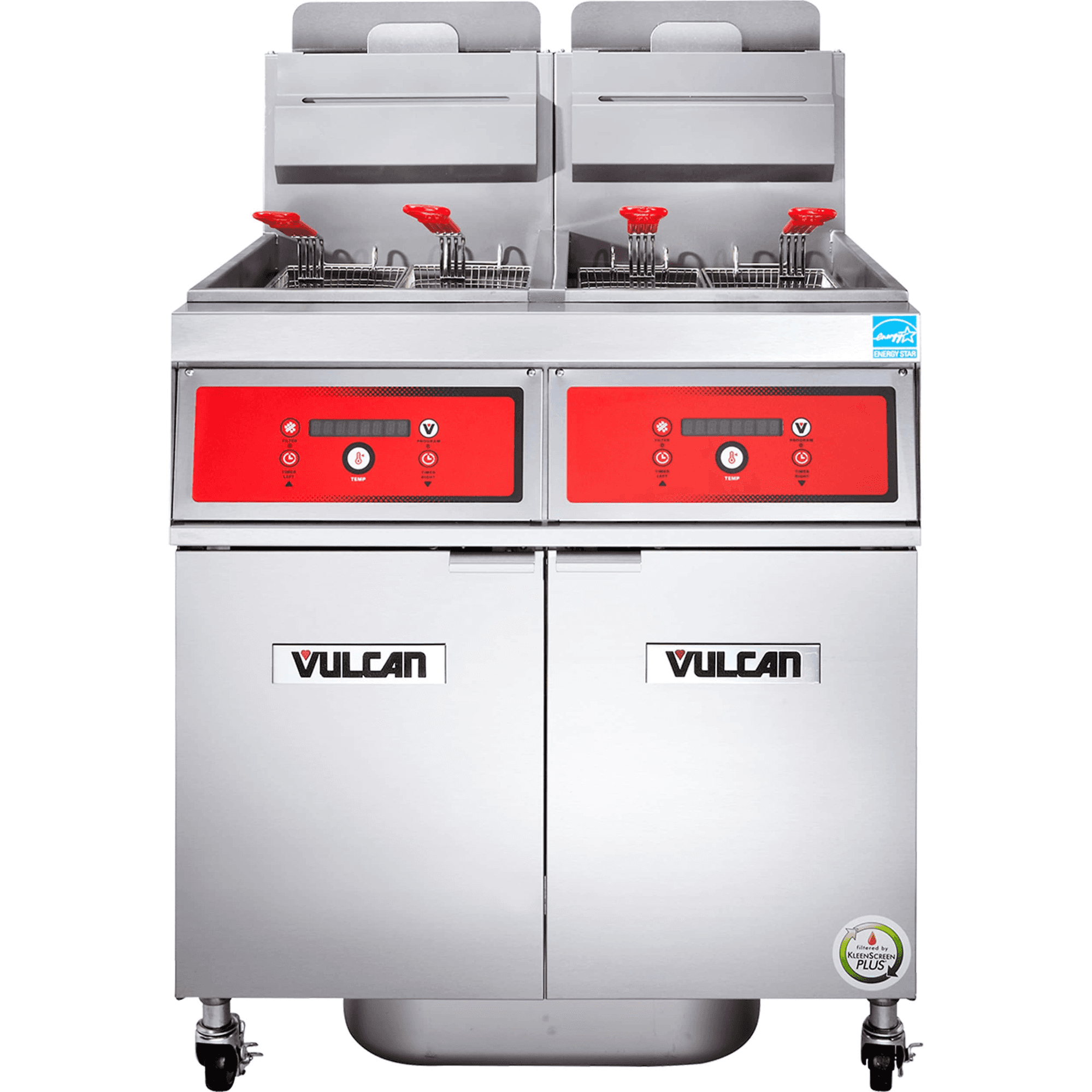

b. Floor Models

Floor models usually have multiple tanks that allow you to fry huge volumes and different varieties of food at the same time. These typically come in tube-type or open pot configurations, which are best for all-purpose applications. Some floor models may also be set up in a battery, or a bank of multiple fryers attached together and share a single gas or electrical connection. Batteries are either sold custom-made or pre-built.

2. Power Source

a. Gas

Gas-powered fryers are more common because gas is normally cheaper in many parts of the country, although the costs of natural gas have increased in some places. Gas fryers usually have their heating elements placed inside the frypot, where they are completely submerged in oil. Because the oil is in direct contact with the heaters, gas takes less time to heat the oil to the desired frying temperatures. They can also reach hotter temperatures than electric fryers.

Natural gas needs a connection to a gas line. If you don’t already have one, paying for a gas hookup can set you back budget-wise. If you need to be able to carry your fryer to outdoor and catering events, a propane fryer is a better option. Unlike natural gas, propane doesn’t need a connection to the building’s main gas supply because it is stored in portable tanks that you can take with you.

b. Electric

Electric fryers use a heating coil that is used to raise the temperature of the oil right away. This makes it more energy-efficient than gas fryers with heating elements outside the frypot, such as open top fryers, which have to heat up the pot first before the oil.

Electric fryers require no gas line connection. They are also very easy to install. You can simply plug them into an appropriate outlet and start frying. However, electricity is more expensive in some localities, which can increase your utilities costs in the long run. Electric fryers may also need backup generators to prepare for sudden power outages.

3. Size and Capacity

There are a few ways to determine the capacity of your fryer. Simply looking at the physical dimensions and counting the number of tanks can help you decide what size of fryer you need for your kitchen. Larger fryers can obviously accommodate more items at a time. Fryers with 3 or 4 tanks can contain higher amounts of oil and produce bigger volumes than single or double-tank units. A countertop fryer can usually contain anywhere from 6 to 47 lbs. of oil, while floor models can contain up to 150 lbs.

As a general rule of thumb, the amount of food a fryer can produce at is roughly double the amount of oil the fryer can contain. For example, if a fryer’s oil capacity is 20 lbs., it can produce around 35 to 40 lbs. of food products. Figure out how much food you need to fry and then double the oil capacity to find the right size of fryer. If you need to produce 20 lbs. of French fries, a fryer with a 10 lbs. capacity will be adequate for your needs.

Don’t forget to consider the available space you have as well. Countertop models will easier fit in tight spaces but won’t be enough in a high-volume production kitchen. Floor models, on the other hand, have larger footprints and will need a lot of space, Also, provide plenty of clearance around the fryer. Whether you have a countertop or floor model, the fryer needs at least 6” of empty space around the sides and back to allow for air to circulate.

4. Types of Food

Fryers are designed to cook two types of food items: dry-coated (breaded) and wet-coated (battered). Dry-coated items produce more sediment while cooking. If you need to make heavily breaded, dry-coated food items, go for a tube fryer. A tube fryer has a large sediment zone where the bits of pieces of food can go and will not scorch.

Wet-coated items produce far less sediment and will not need as big of a sediment zone as breaded products. What battered food products need are a flat bottom fryer that allow the items to rise to the top of the fryer once cooking is done. If you need to cook different types of food, a tube fryer or an open top fryer are versatile enough for most frying purposes. You can also opt for different kinds of fryers to accommodate specific food types.

5. Ease of Use and Cleaning

A fryer should be able to function properly to help avoid stress inside the commercial kitchen. It must have the right features that make it easy to use and staff must be given the right training for them to be able to handle the equipment without issues.

Also, consider the ease with which staff can clean and maintain a fryer. Most fryers are not easy to clean. Tube fryers pose the biggest challenge because of the tube-shaped heaters obstructing the bottom of the frypot. On the other hand, flat bottom fryers provide easy access to every nook and cranny of the frypot.

A fryer must also have an oil drain, which is typically located in front of the unit or hidden inside just underneath the frypot. The oil drain is useful for draining the oil every few months so you can give the fryer a thorough manual scrubbing.

6. Safety

Fryers must be positioned underneath a commercial hood system, which extracts grease, fumes, and smoke from the air to maintain a safe and cool working environment. Having the right ventilation equipment in place also keeps carbon monoxide from accumulating in the air. Check with your local fire and safety codes to determine the specific hood and ventilation systems you need in place.

7. Accessories

Plenty of accessories help make using the fryer more convenient.

a. Fryer Baskets

Fryer baskets hold food items as they’re cooking in oil. This prevents them from sinking to the bottom of the frypot and getting scorched by the heating elements. Most fryers come with their own baskets, but having a few extras may come in handy in the future.

b. Fry Dump Stations

Fry dump stations have top or bottom burners that provide heat to keep finished food products warm and crunchy before they are served. These usually have grates to hold the food items and a crumb tray to gather any food sediments. High-end fryers may have their own dump stations, although most models need to have one purchased separately. Some units may also have a shelf for holding packaged food items that are ready for takeout or delivery.

c. Fryer Screens

Also called grates, fryer screens are positioned above the burners to capture food particles and prevent them from reaching the heaters. These are either flat of have handles so you can remove them more easily during cleanup.